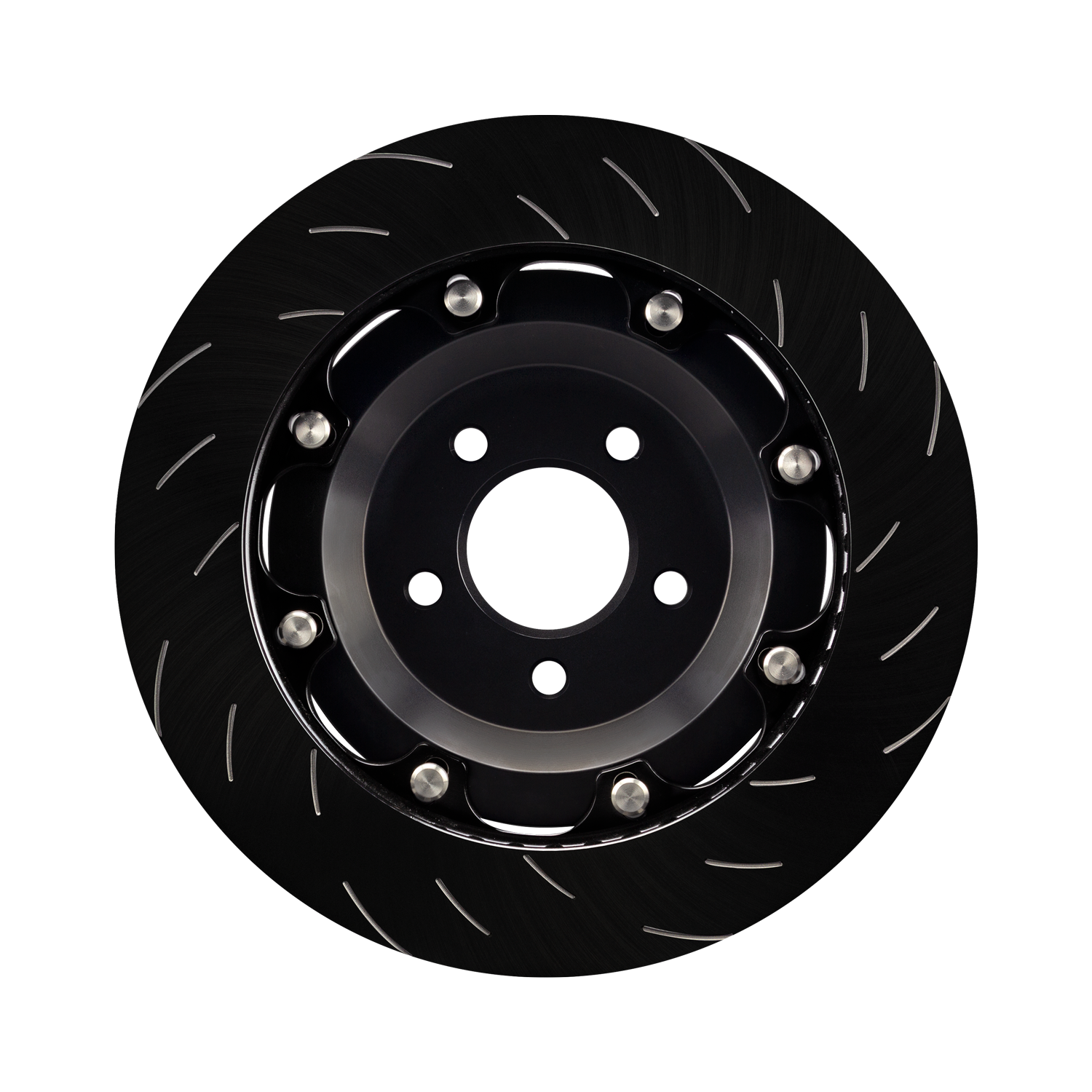

Fully Floating…

After an extensive development program, thousands of hours dyno testing, and the construction of a brand-new production line at the EBC Brakes World Headquarters in Northampton, UK, EBC are pleased to launch a new range of high performance 2-piece fully-floating brake rotors under the newly formed EBC Brakes Racing sub-brand.

Embarking on this project, the EBC Brakes Racing team’s mission was a clearly defined one; to develop the highest quality 2-piece floating brake rotor available on today’s marketplace. The componentry and technology used in these brake rotors exemplifies this pursuit of ultimate and absolute quality, culminating in a brake rotor that is perfectly matched to the highest braking demands of modern performance road and race cars.

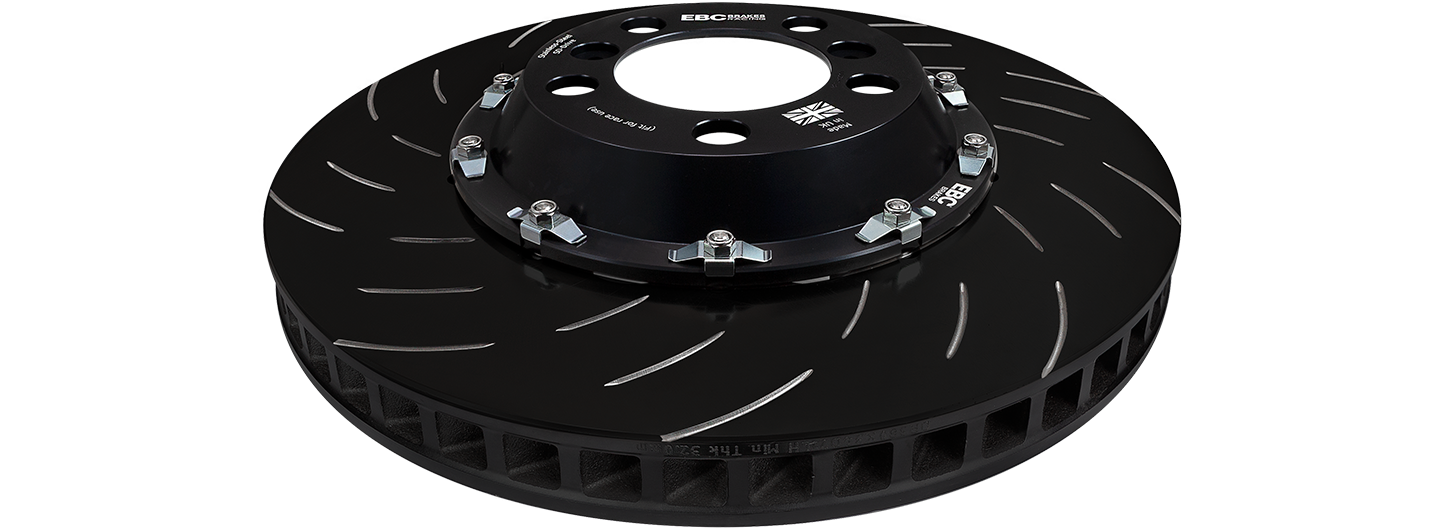

G3500 Disc Alloy Friction Rings

Every outer ring is cast from the highest-grade disc alloy ‘G3500’. Derived from race technology and having a high carbon and high copper metallurgy, G3500 disc alloy has superior thermal conductivity and heat cycling durability for maximum brake rotor life and performance, particularly during harder driving or track driving.

Highest Of Quality

EBC Brakes Racing would like to emphasise that we put as much effort into the development of our rotor metallurgy as we put into the development of our pad friction materials. The pad and rotor combined form the friction coupling; if either component is of poor quality then the outcome will likely be poor overall system performance. The best brake pad in the world used on a low-quality rotor with bad metallurgy will result in merely average overall performance since the pad will not be able to deposit the ‘transfer layer’ onto the brake disc that is critical to high brake system performance. For this reason, EBC Brakes Racing uses only the highest quality disc alloy available. In the production process, these cast iron rings are balance checked, metallurgy checked, and then precision double disc ground for perfect accuracy and flatness to within microns. In addition, the centre hub, stainless steel bobbins, pressure clips, and hardware are all 100% made at the EBC racing facility in the UK to guarantee precision quality and function.

The Benefits

The benefits of using a high-performance metallurgy are evident after testing EBC Brakes Racing’s 2-piece floating rotors against the recently introduced and extremely harsh ‘Reg 90’ dynamometer routine. The EBC 2-piece rotors completed two full test cycles back-to-back with zero disc cracking and no visible disc crazing. To put this into perspective, most OE discs show signs of cracking at stop 40 and then fail at 50% through just one R90 test, at stop 80 of 150. The quality of EBC’s metallurgy coupled with the fact that the disc is fully-floating in its design allows EBC’s 2-piece rotors to outperform most OE discs by a factor of over 4x in the ‘R90 Thermal Fatigue Test’.

EBC Brakes Racing’s 2-piece fully floating rotors have been tested to withstand hundreds of hours the harshest track driving

However, these rotors are not a track only product. Features such as anodised hubs, stainless-steel hardware and the incorporation of anti-rattle clips mean these rotors are road friendly, making them the perfect choice for customers who enjoy regular track days yet also drive their cars on the public highway.